Blog

Unlocking Value: The Rising Market for Scrap Parts in the Circular Economy Revolution

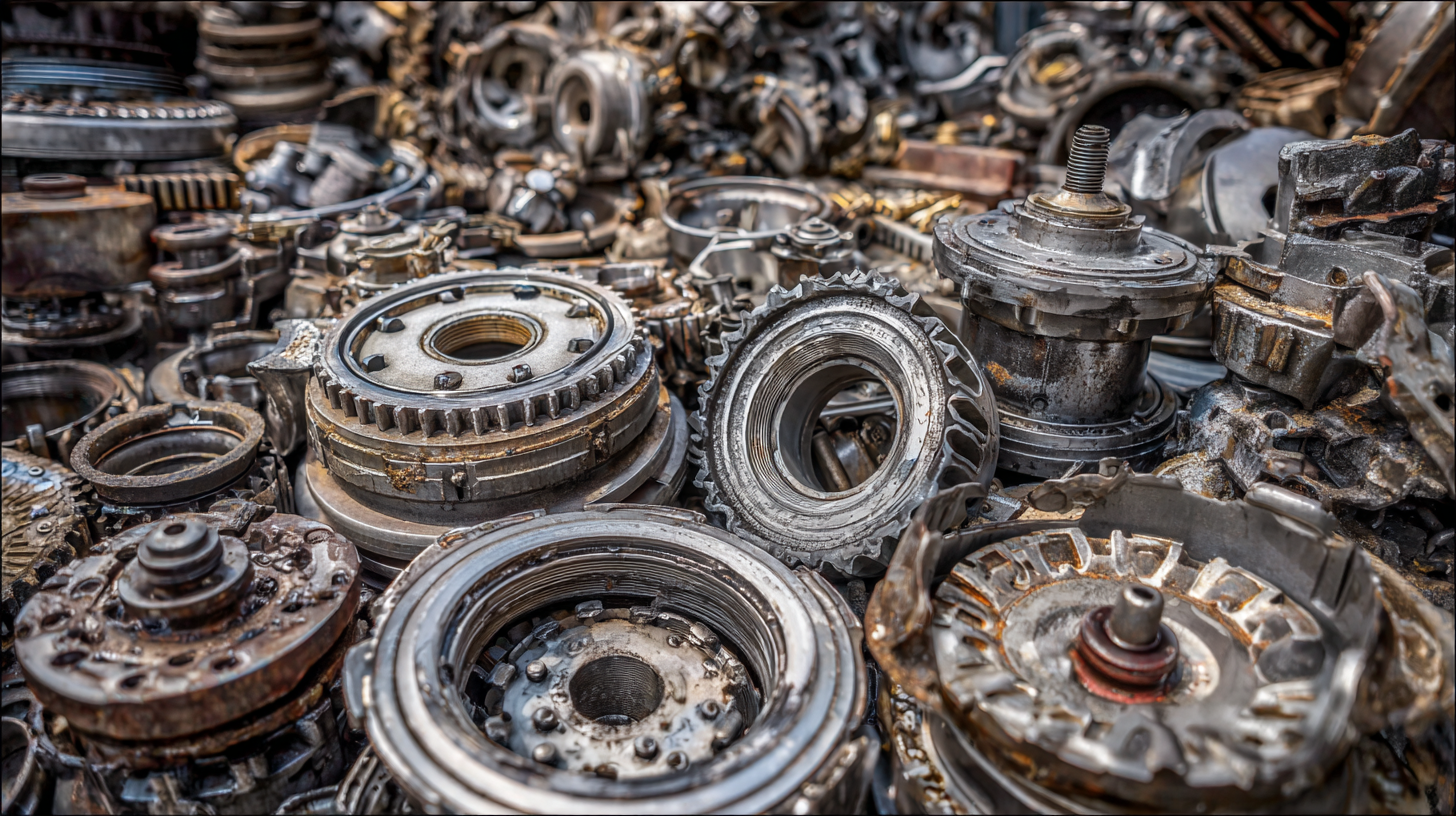

The global shift towards a circular economy is transforming industries, and the market for scrap parts is burgeoning as a result. According to a report by the The Global Circular Economy Foundation, the recycling of scrap parts can potentially generate over $1 trillion in economic benefits by 2030. This reflects a growing recognition of the value embedded in discarded materials, with the International Resource Panel estimating that up to 70% of industrial materials can be recycled or repurposed. The rising demand for sustainable practices is nudging manufacturers to reconsider their waste management strategies, leading to an increase in the sourcing and utilization of scrap parts. As businesses prioritize efficiency and sustainability, the importance of scrap parts in reducing costs and minimizing environmental impact is becoming more apparent, positioning them as valuable assets in the drive towards a regenerative economy.

Identifying High-Value Scrap Parts: Strategies for Efficient Recovery

The circular economy emphasizes the importance of extending the lifecycle of products and materials, and scrap parts play a crucial role in this paradigm shift. Identifying high-value scrap parts is essential for maximizing resource recovery and minimizing waste. Industries can employ several strategies to enhance the efficiency of scrap recovery processes. For instance, conducting thorough assessments of materials and components at the end of their useful life enables companies to determine which parts can be salvaged for reuse or resale.

Another effective strategy is the implementation of advanced sorting technologies, such as AI-driven systems and automated separation tools. These technologies can significantly improve the accuracy of identifying valuable scrap parts, reducing human error and increasing processing speed. Moreover, collaborating with strategic partners and establishing a robust network for the exchange of scrap parts can foster innovation and open new markets. By focusing on these strategies, businesses can unlock the hidden potential of scrap parts, driving economic benefits while contributing to environmental sustainability.

Assessing Market Trends: Understanding Demand for Scrap Parts in Circular Economy

The rising market for scrap parts is a significant aspect of the circular economy revolution, reflecting a growing demand for sustainable practices across various industries. The shredding machine market, valued at approximately $2.616 billion in 2024, is projected to reach an impressive $4.705 billion by 2032, showcasing a compound annual growth rate (CAGR) of 7.6%. This trend indicates a heightened interest in recycling and proper waste management, as businesses and consumers alike strive to minimize environmental impact.

As industries pivot towards circularity, the demand for scrap parts is increasingly becoming a focal point for innovation and growth. Companies are recognizing that scrap parts not only offer significant cost savings but also contribute to resource conservation and reduced waste. The shift in consumer preferences towards eco-friendly products further reinforces this demand, emphasizing the need for businesses to adapt their strategies to meet evolving market expectations in an era defined by sustainability.

Innovative Techniques for Scrap Part Recycling and Reuse

The circular economy revolution has led to significant innovations in the recycling and reuse of scrap parts, creating a vital market that not only contributes to sustainability but also enhances economic value. According to a report from the Ellen MacArthur Foundation, transitioning to a circular economy could generate $4.5 trillion in economic benefits by 2030. Key techniques in the recycling process have evolved, such as advanced sorting technologies powered by artificial intelligence, which improve efficiency in identifying and separating scrap materials with greater precision.

Moreover, the adoption of hydrometallurgical processes has been pivotal in extracting valuable metals from electronic waste, yielding recovery rates that can exceed 90% for precious metals compared to traditional methods. A study from the World Economic Forum indicates that if e-waste recycling rates were to reach 20% globally, up to 1.2 million tonnes of additional gold and silver could be recovered annually. These innovative methods not only reduce landfill waste but also encourage industries to view scrap parts not as waste, but as resources ripe for reclamation and reuse, further aligning with the principles of a sustainable economy.

Unlocking Value: The Rising Market for Scrap Parts in the Circular Economy Revolution

Building Partnerships: Collaborating with Stakeholders in the Scrap Parts Market

In the burgeoning landscape of the circular economy, the scrap parts market presents a unique opportunity for stakeholders to collaborate and create value. Partnerships among manufacturers, recyclers, and consumers are essential to bolster the efficiency of resource recovery. By sharing knowledge and aligning goals, these stakeholders can not only minimize waste but also unlock new revenue streams through innovative uses of scrap materials. Emphasizing collaboration fosters a community approach where businesses can share best practices and improve processes.

Tips for Building Effective Partnerships:

- Identify common goals: Ensure all stakeholders have aligned objectives to drive collaboration effectively.

- Establish clear communication: Regular check-ins and open dialogue can help mitigate misunderstandings and streamline workflows.

- Leverage technology: Utilize data-sharing platforms and management tools for improved coordination and transparency among partners.

Engaging in this multi-faceted collaboration allows businesses to thrive in the scrap parts market while contributing to sustainability. As organizations unite in their efforts, they set the stage for a robust ecosystem that not only prioritizes environmental stewardship but also fosters economic growth.

Unlocking Value: The Rising Market for Scrap Parts in the Circular Economy Revolution

| Category | Market Size (USD Billion) | Growth Rate (%) | Key Stakeholders |

|---|---|---|---|

| Automotive Scrap | 23.5 | 4.7 | Recyclers, OEMs, Distributors |

| Electronics Scrap | 19.3 | 6.1 | Recyclers, Insurers, Retailers |

| Industrial Scrap | 15.6 | 5.3 | Manufacturers, Recyclers, Government |

| Construction Scrap | 12.4 | 3.8 | Contractors, Waste Management Firms, Recyclers |

| Metal Scrap | 21.7 | 5.5 | Scrap Traders, Foundries, Recyclers |

Creating a Sustainable Business Model: Monetizing Scrap Parts in the Circular Economy

The circular economy represents a transformative approach to sustainability, emphasizing the need to recycle and repurpose materials rather than simply dispose of them. Monetizing scrap parts within this framework not only promotes environmental responsibility but also opens significant avenues for profit. According to a report from McKinsey, the global market for recycled materials is projected to grow significantly, reaching an estimated value of $200 billion by 2025. This delineates a vital opportunity for businesses to pivot towards sustainable practices while simultaneously generating revenue from what was once considered waste.

The sustainable business model hinges on efficient scrap part recovery and innovative recycling processes. The Ellen MacArthur Foundation underscores that transitioning to a circular economy could yield $1 trillion in economic benefits annually, demonstrating the financial viability of integrating scrap materials into product life cycles. Companies investing in the retrieval and resale of scrap parts can enhance their brand reputation while tapping into an expanding market driven by eco-conscious consumers.

Businesses that embrace these principles stand to benefit not only from recovered value but also from a competitive edge in an increasingly sustainability-focused marketplace.

Related Posts

-

Exploring Junk Parts Innovations at the 2025 China 138th Canton Fair

-

Exploring the Evolution of Automotive Body Parts: From Classic Designs to Modern Innovations

-

The Future of Eco Cars Exploring Sustainable Innovations for a Greener Planet

-

Innovating Auto Recycling Strategies at the 138th Canton Fair 2025 Insights and Industry Data

-

Understanding the Impact of Quality Car Auto Parts on Vehicle Performance and Safety

-

Why Automotive Body Parts Are Crucial for Vehicle Safety: Understanding the Industry Standards and Impact

Logel’s Auto Parts

116 Bridge St East

Kitchener, Ontario

N2K 1J6

Phone: 519-745-4751

Toll Free: 1-800-818-9118

Hours 8:00-5:00 Monday to Friday

At Logel’s Auto Parts, we serve a range of communities in Southern Ontario, including: